Professional manufacturer of pneumatic components for over decades

We have focused on producing valves, cylinders, and other pneumatic-related products with a high brand reputation and rich industrial application experience.

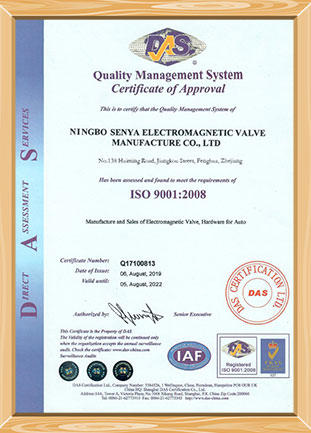

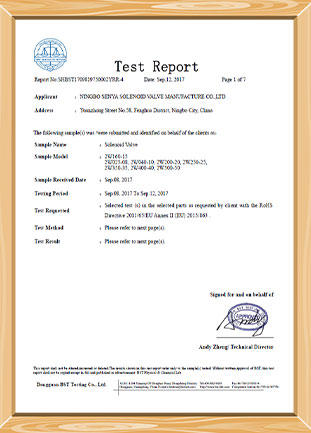

Commitment To Superior Quality

Recent News

-

How is the pressure of compressed air in the cylinder regulated?

1. Compressed air: the secret of the source of powerThe power source of the automated cylinder lies in compressed air. This clean and efficient form o...

-

How is the automatic lubrication pump integrated with the cylinder system?

Innovation and integration, reshaping the new standard of industrial lubricationThe automatic lubrication pump design of the SC series tie-rod cylinde...

-

How does a multi-stage filtration system ensure that pollutants are intercepted layer by layer?

Today's air quality is becoming increasingly important. In order to ensure the stable operation of pneumatic systems, air compressors and various prec...

-

How customizable is the directional valve intelligent indicator light system?

In the field of industrial automation, directional valves are key components for controlling the direction of fluid flow. Their performance and intell...

-

What are the sealing requirements for pneumatic control valves in flammable environments?

In a flammable working environment, any slight negligence may bring about serious consequences. For pneumatic control valves, a key device for control...

-

What are the clear advantages for users of choosing a hard anodized valve body?

The reliability and durability of solenoid valves have become important standards for measuring product quality in the modern industrial field. In ord...

-

How are the scraper rings of ISO 15552 cylinder pneumatic actuators designed to work with the piston rod and cylinder wall?

The scraper ring design of ISO 15552 standard cylinder pneumatic actuator plays a vital role in the pneumatic system. It can effectively prevent dust ...

-

The company appeared at the 2023 Indonesia Trade Expo to showcase its strength in industrial equipment and components

From November 23 to 25, 2023, the Indonesia Trade Expo and Indonesia Industrial Equipment and Parts Joint Exhibition opened brilliantly in Hall A of t...

-

How to properly install and maintain Directional Manifold in industrial systems to ensure efficient operation?

In modern industrial systems, Directional Manifold plays a vital role. These components are used not only to control the flow direction of fluids, suc...

-

How to select and configure efficient Air Treatment Units to adapt to different industrial environments?

In modern industrial environments, air quality is critical to the health of workers and the proper operation of production equipment. Therefore, selec...

简体中文

简体中文 English

English Русский

Русский